The GRUNDORAM rammers are compressed air driven pipe jacking machines with a thrust capacity of up to 40,000 Nm. They are used for pipe jacking under roads, railway tracks and rivers in all soil types except mud, swamps and non-displaceable, rocky soils.

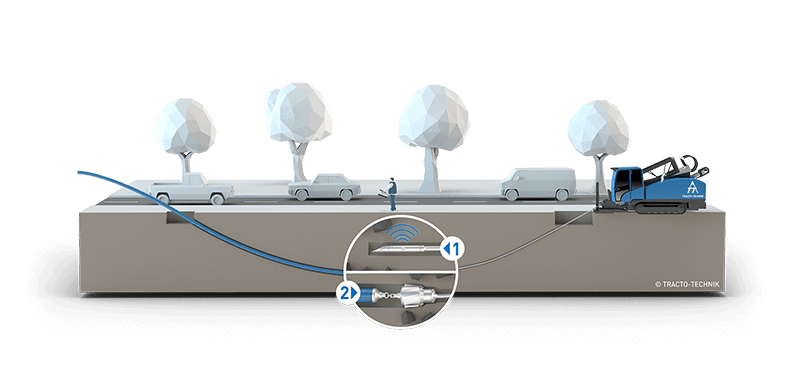

The most common method of driving with GRUNDORAM is dynamic pipe jacking using the ramming method. In this process,media or protection pipes up to 4,000 mm in diameter are installed underneath roads, railway tracks and rivers up to 80 m in length without pressing abutments.

Target precision is achieved because the Grundoram’s dynamic impact punches through the ground, destroying obstacles so they need not be displaced in one piece and shoved rammed forward. The soil which is taken up by the open steel pipe during pipe jacking is finally expelled into the target pit using compressed air and/or water.

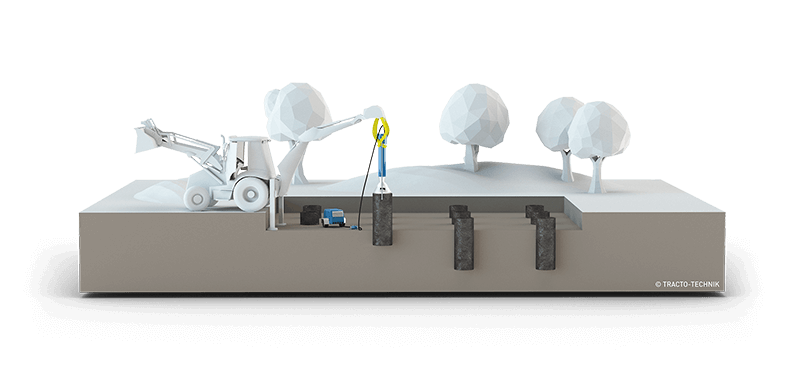

With the appropriate accessories, GRUNDORAM pipe jacking machines can also used vertically as a pile driver, to support HDD drilling (HDD Assist & Rescue) and as pipe cracker for dynamic piperenewal.

- 13 models with thrust forces from 180 Nm to 40,000 Nm

- Particularly robust, resilient and reliable pipe jacking machines

- High target accuracy in pipe jacking using the ramming method

- Long service life due to one-piece housing and elaborately tempered piston

- No press abutments required for pipe jacking, which significantly reduces set-up times

- Mini machines for confined spaces and reverse gear for easy release of pile-driving accessories

- Versatile applications, i.e. horizontally as pipe rammer, vertically as pile hammer, as pipe cracker for dynamic pipe renewal and for pipe rehabilitation

APPLICATION RANGE OF GRUNDORAM

DYNAMIC PIPE JACKING

- Horizontal crossings underneath streets, rivers, railway embankments, buildings and closed surfaces

- Vertical application as pile driver

- Pipeline construction up to ND 4.000

- HDD Assist & Rescue

DYNAMIC PIPE BURSTING

- Pipe renewal in the existing pipe path using dynamic pipe bursting method, also with cross-section enlargement

- Pipe rehabilitation using calibre pipe bursting, also with reduction of the pipe’s cross-section

- Pipe rehabilitation using the Tight-In-Pipe method

- Horizontal application for the construction of underpasses, smaller culverts and pipe screens for tunnel construction

- Vertical application for foundations and pile driving, well construction, ramming of sheeting walls

- HDD-Assist & Rescue to support horizontal directional drilling

- Conductor Barrel:

In soils which are impossible to bore through, a steel pipe is rammed through the relevant soil layer so the HDD operation can commence - Pull-back assist:

When pulling in steel pipes for HDD, the GRUNDORAM can give dynamic support or release pipes if they become jammed. The ramming machine is connected to the steel pipe in the rear to allow the application of impact energy, synchronised with the pulling speed - HDD Rod Recovery:

Pulling out trapped drill rods with the aid of an adapter and dynamic ramming force - Bore salvage:

Retrieving jammed product casing pipes after the HDD operation