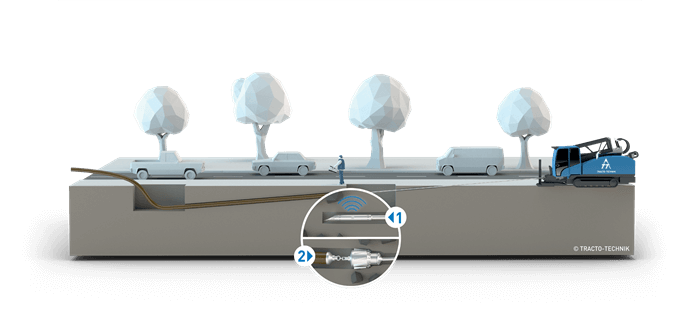

Horizontal auger boring is a reliable static method for installing sewer house connections as well as product and steel protection pipes underneath streets and railways tracks. Installation can be either directional or non-directional. With directional thrust bores, the highest levels of on-target precision, as required in sewer constructions, are achieved.

The compact GRUNDOBORE 200S auger drill, which is is driven hydraulically by an external hydraulic unit, is particularly suitable for installing sewer house connections and product and protection pipes up to OD 280. With this standard application, first a pilot drill rod is thrusted forward. Then an auger drill bit is connected to the rods, which transports the soil into the target pit as it is pulled back. At the same time, protection pipes are pulled in into which the product pipes are finally pressed.

Since the GRUNDOBORE 200S‘s support frame and auger boring unit can be installed separately, launching is possible from a 1 m-manhole or an exceptionally small working pit.

- Horizontal auger boring is particularly suitable for the precise installation of sewer house connections, product or protection pipes

- Exceptionally high positional accuracy with controlled driving in the pressure-drilling process

- Start of the press drilling system from a 1 m circular shaft or an extremely small construction pit

- Thrust bores for sewer service connections

- Undercrossing of streets and railway tracks

- Linear HDD bores

- Static pipe bursting