GRUNDOBORE – 200S

The Horizontal Auger boring method is a reliable static process for installing sewer house connections as well as product and steel protection pipes under streets and railways tracks. Installations can be either steered or non-steered. With the steered method in sewer construction, high levels of on-target precision required in sewer construction can be achieved.

The compact GRUNDOBORE 200S is powered by an external hydraulic station with hydraulic drive energy and is particularly suitable for installing sewer house connections and product and protection pipes up to DA 280.

Since the GRUNDOBORE 200S support frame and auger boring unit can be installed separately, launching is possible from a 1 m-manhole or exceptional small work pit.

GRUNDOBORE

SYSTEMATIC PRECISION

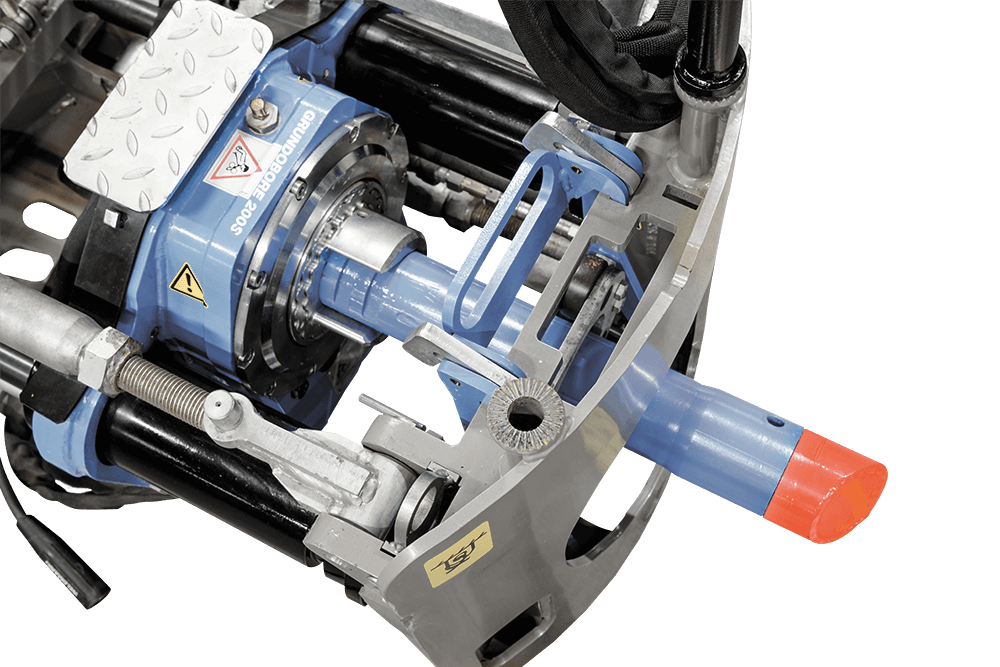

ROTARY DRIVE

With quick-locking rods – simple rod connection, no screwing together at the rotary drive.

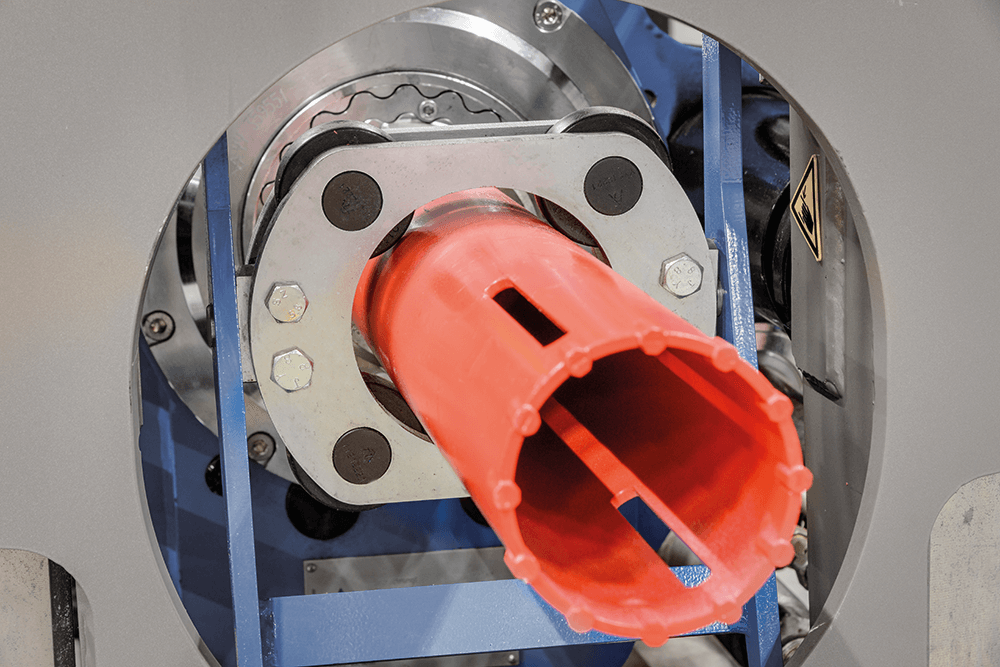

CORE BIT GUIDE

Precise spot drilling of the manhole wall.

BORE DIRECTION

Vertical adjustment of the drilling direction by +/- 11 % is possible after installing the machine.

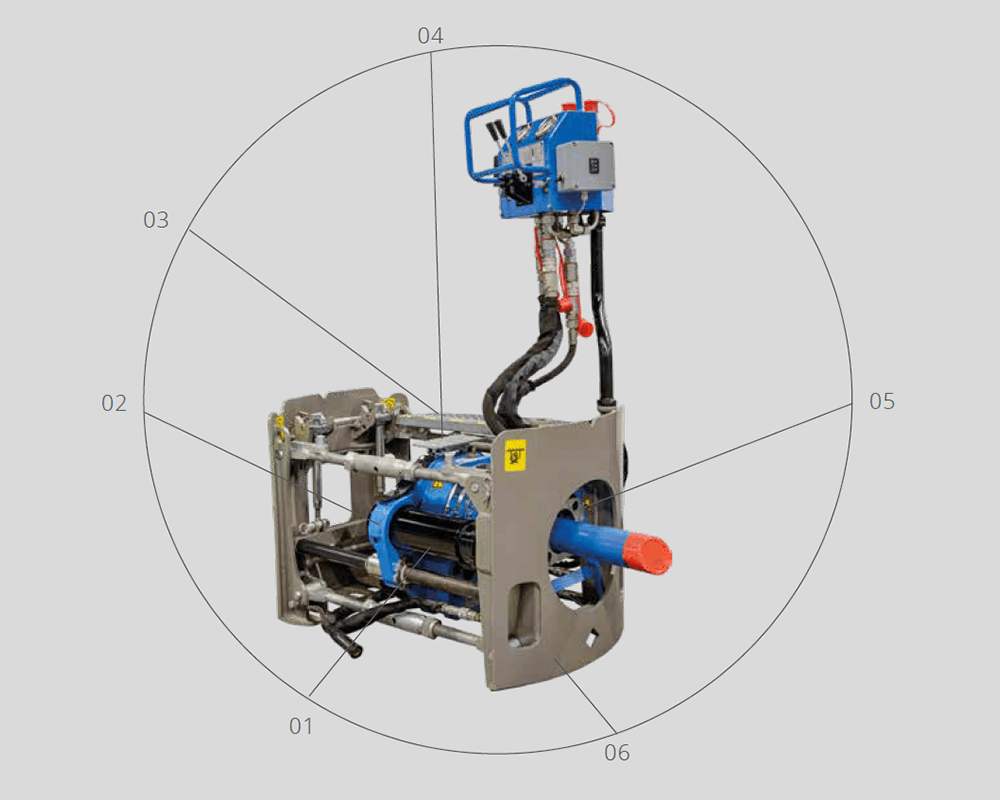

01. Long stroke for extremely short construction lengths – effective rod length of 450 mm

02. Compact powerful rotary drive – installation of large pipe diameters in the most limited of spaces

03. Galvanised grid – safe base stand operator to stand on

04. Thrust locking via foot pedal – for ease of operation

05. Mechanical, close-fitting rod clamp – safe rod release, minimum wear and tear

06. Semi-circular support plates – secure bracing in a 1 m manhole

TECHNICAL SPECIFICATIONS

MANHOLE OR PIT LAUNCHING

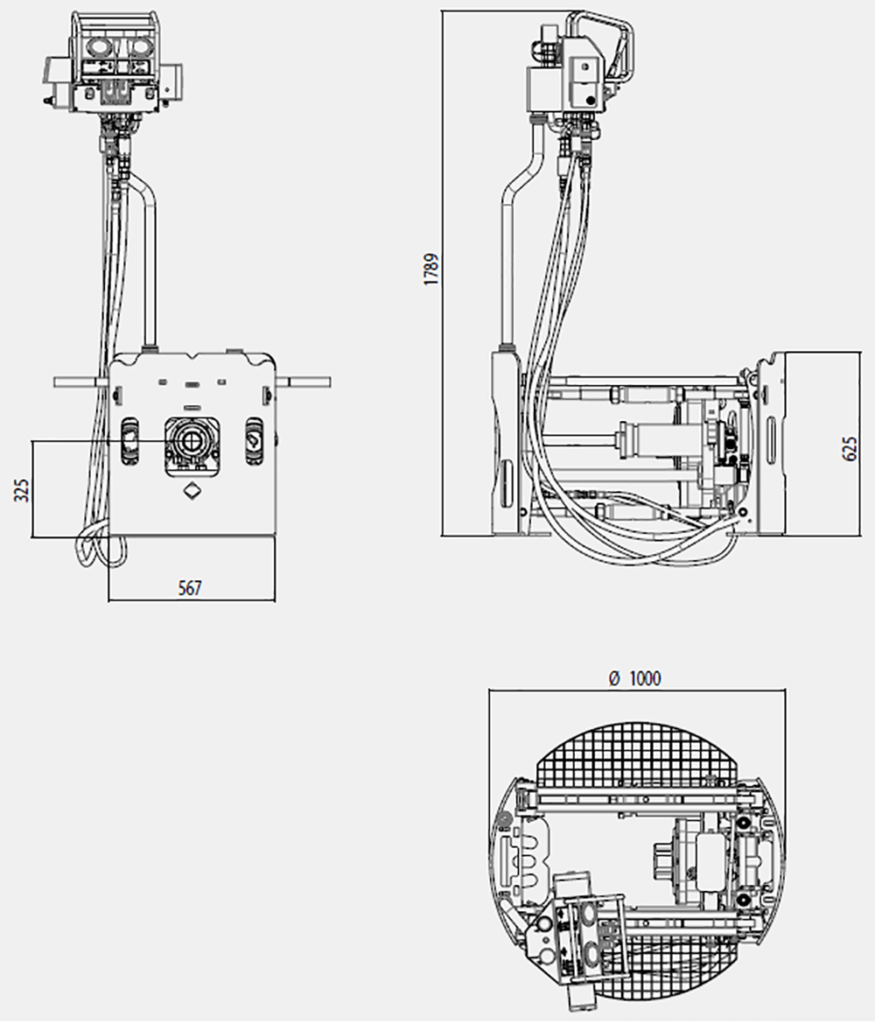

- For launch from a 1 m circular manhole with a fracture opening of only Ø 62.5 cm, the rig can be disassembled into its single components (bore drive with pressing cylinders/ pressing frames).

- Support launch frame for pit launch.

The plateaus of the Swabian Alb mountain range are characterised by rocky ground. Places such as Neuhausen ob Eck (770 m above sea level), on the plateau of the Heuberg region, located on the southwest Swabian Alb, already have rocks not very deep below the earth’s surface, which makes pipeline construction more difficult.

For the drinking water supply to the new industrial estate in the east of the town it was necessary to cross a former main road (B 311), which as a district road (K 5945) is now a very important access road. Because this access road cannot be damaged, the new drinking water main line could only be installed trenchless. It became apparent that the auger boring method also functions reliably in rocky ground.

TECHNICAL SPECIFICATIONS

| PERFORMANCE DATA | GRUNDOBORE 200S metrical | GRUNDOBORE 200S imperial |

|---|---|---|

| Max. thrust force: | 200 kN | 44,961.80 lbf |

| Max. pulling force: | 250 kN | 56,202.25 lbf |

| Cylinder stroke: | 280 mm | 11.02 in |

| Max. thrust speed: | 2 m/min | 78.74 in/min |

| Max. torque: | 3.800 Nm | 2,802.88 lbf ft |

| Max. spindle speed: | 60 U/min | 60 rpm |

| max. hydraulic pressure: | 250 bar | 3,625.95 psi |

| Length x Width x Height: | 960 x 570 x 630 mm | 37.80 x 22.44 x 24.80 in |

| Weight: | 400 kg | 881.84 lbs |

| Axis height/axis height with steel frame application (pit launch): | 325/375 mm | 12.80/14.76 in |

| Launch manhole (circular manhole): | Ø 1 m | Ø 3.28 in |

| Length of launch pit: | 1,2 m | 3.94 ft |

| Length of target pit: | 1 m | 39.37 ft |

| Effective length of pilot rods: | 450 mm | 17.72 in |

| Diameter of pilot rods: | 82,5 mm | 3.25 in |

| Retrievable pipe/effective length: | 450 mm | 17.72 in |

| Max. outside pipe diameter: | 280 mm | 11.02 in |

| Max. bore length (depends on soil conditions): | 25 m | 82.02 ft |