- Advanced Equipment for Utilities Infrastructure

- +30 2310 623-599

- info@domka.gr

SOIL COMPACTORS CR

The reversible CR soil compactors stand out above the competition with their superb compacting capacity and superior efficiency. Machines made by Weber MT are always the number one choice – whether they are needed for classic applications in road building and civil engineering or for embedding paving stones. Their balanced operating characteristics and exceptionally smooth operation with low hand-arm vibrations provide for superb ease of use.

REVERSIBLE SOIL COMPACTOR CR 2

The light all-rounder

- Infinitely variable forward and reverse travel.

- Variable hydraulic shifting allows for superior accuracy even when working in challenging areas.

- Work without getting tired thanks to a height-adjustable guide bar and low hand-arm vibration handles.

- Engine protection frame and cover to protect life of machine and engine.

- Standard feature: integrated and rugged wheel kit.

REVERSIBLE SOIL COMPACTOR CR 3

The all-rounder

- Hydraulic control for infinitely variable forward and reverse travel.

- Low hand/arm vibrations.

- Work without getting tired thanks to a height-adjustable guide bar and low hand-arm vibration handles.

- The engine is protected against external damage by a rugged protection frame and engine cover.

- Low maintenance requirements thanks to the centrifugal clutch with automatic tensioning feature.

- Simple maintenance as all maintenance components are easily accessible.

- Safe and quick loading thanks to the large, floding lifting eye.

- Higher operating convenience with electric starter.

Apart from the standard features including E-start, other features are also offered for CR 6 to CR 9 soil compactors with Hatz diesel engine. The features available in the “MDM” and the “CCD 2.0” versions of these models include, respectively, an engine data management system and the COMPATROL® compaction control system. Also available is WSA (Weber Smart Assist).

REVERSIBLE SOIL COMPACTOR CR 7

Performance and comfort in perfection

AVAILABLE ACCESORIES

- Extension plates.

- Polyurethane pad.

- Infinitely variable hydraulic shifting mechanism used for forward and reverse travel.

- Low hand-arm vibrations.

- To ensure they are protected, hydraulic hoses are located inside the guide bar.

- Work without getting tired thanks to a height-adjustable guide bar.

- The engine is protected against external damage by a rugged protection frame and engine cover.

- Low maintenance requirements thanks to the centrifugal clutch with automatic tensioning feature.

- Simple maintenance as all maintenance components are easily accessible.

- Quick and safe loading thanks to large, hinged lifting eye.

- Can be lashed securely for transport thanks to additional eyelets in the engine console.

- Flexible operation with regards to working widths thanks to extension plates.

- E-start with operating hour meter as well as oil and voltage control

- Road building, civil engineering, landscape/Hardscape and building construction.

- Compaction of paving stones.

- Sand and gravel compaction applications.

- Infinitely variable hydraulic shifting mechanism used for forward and reverse travel.

- Precise, reliable and convenient switch between forward and reverse travel.

- Low hand/arm vibration.

- To ensure they are protected, hydraulic hoses are located inside the guide bar.

- Work without getting tired thanks to a height-adjustable guide bar.

- The engine is protected against external damage by a rugged protection frame and engine cover.

- Low maintenance requirements thanks to the centrifugal clutch with automatic tensioning feature.

- Simple maintenance as all maintenance components are easily accessible.

- Quick and safe loading thanks to large, hinged lifting eye.

- Flexible operation with regards to working widths thanks to extension plates.

- E-start with operating hour meter as well as oil and voltage control

- Improved operational safety thanks to MDM engine management for air filter, oil pressure, battery voltage, etc.

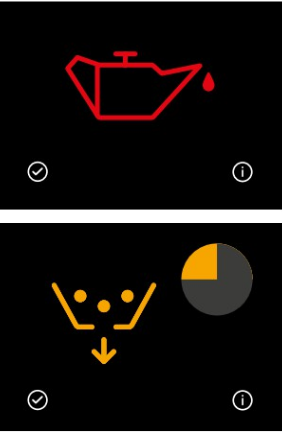

ENGINE PROTECTION MDM

Reversible soil compactors CR 6 MDM, CR 7 MDM, CR 8 MDM, CR 9 MDM

To increase safety in every-day life at the construction site, Weber MT will rely on comprehensive engine data management system from now on. MDM-engine protection constantly checks all essential parameters of the engine: The engine will shut-off automatically if the MDM discovers that the engine oil pressure / oil level is too low, the engine temperature is too high or the air filter is full. If this happens, the operator is notified accordingly by an LED indicator. This safeguard makes disastrous engine failures caused by insufficient maintenance a thing of the past. Better still, the system also indicates when the engine needs to be serviced. E-start and hour meter are standard.

COMPATROL® 2.0

The continuous compaction control system

Reversible soil compactors CR 6 CCD 2.0, CR 7 CCD 2.0, CR 8 CCD 2.0, CR 9 CCD 2.0

The compaction control COMPATROL® 2.0 enables even more constant and comprehensive compaction. Weak points can be easily recognized and – what is important – repaired in time. Therefore, less passes are necessary. That saves time and money. Up to 25% of time can be saved with the help of COMPATROL® CCD 2.0.

The MDM engine protection is already included in COMPATROL® CCD 2.0. Thereby it offers double safety.

MDM version plus the following features

- COMPATROL® 2.0 allows for uniform compaction across the entire compacted surface.

- Weak points in the soil can be detected and corrected quickly.

- Easy-to-understand and self-explanatory LED display.

- Savings in cost/time of up to 25% due to fewer passes.

How the compaction control COMPATROL® 2.0 works:

The base plate of the soil compactor is fitted with a sensor. This sensor measures the changes in vibration characteristics during compacting to calculate the soil stiffness. The result is indicated to the operator with an LED scale on the display. If no additional diodes turn on while the next pass, that means: Maximum compaction has been achieved.

WEBER SMART ASSIST

The Weber Smart Assist (WSA) merges the COMPATROL® compaction control with comprehensive engine protection and user assistance into a congruous unit.

Symbols indicate to the operator when the engine protection has detected an error – for example, a clogged air filter or insufficient oil pressure.

The so-called info screen provides the operator with scores of data about the engine and the machine.

The Weber Smart Assist is part of the soil compactors CR 6 WSA, CR 7 WSA, CR 8 WSA and CR 9 WSA. Machines of this product range are also equipped with Hatz diesel engines with E1 technology.