THE NEW GRUNDODRILL GENERATION

THE NEW DIMENSION OF DRILLING

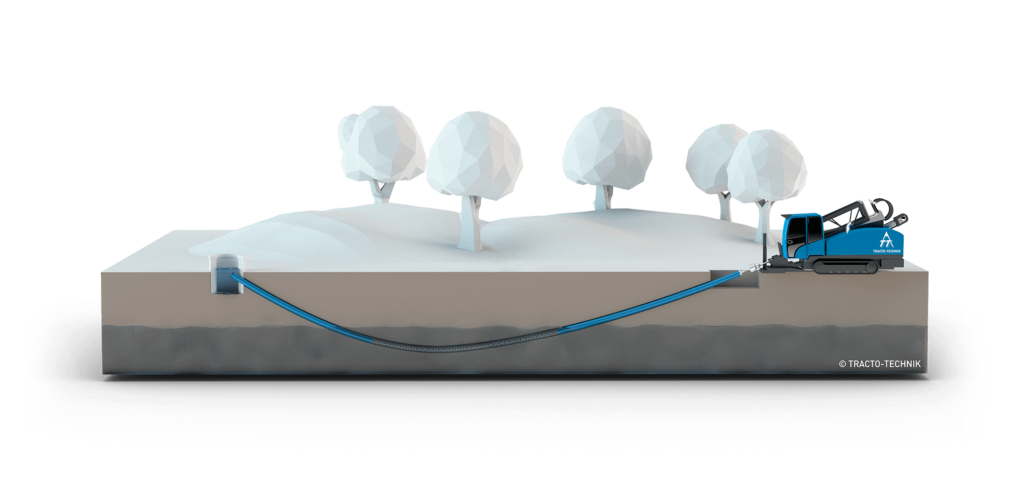

Horizontal Directional Drilling is a complex process, which places equally diverse demands on machine technology. The intensive examination of these requirements from the user’s point of view led to a unique development process in which we questioned every detail and rethought every component. The result is the new GRUNDODRILL generation with a ground-breaking concept, allowing for utmost flexibility and maximum productivity in steerable trenchless pipe installations. Thanks to the trend-setting combination of innovative technology and maximum digitisation, this is easier than you may think – or “simple & easy” as we say.

WITH THE NEW GRUNDODRILL GENERATION, TRACTO-TECHNIK OFFERS A COMPLETE SERIES WITH SIX MODELS IN THE PERFORMANCE CLASSES FROM 60 TO 280 KN, WITH THE INTEGRATED CONCEPT CONVINCING IN EVERY RESPECT.

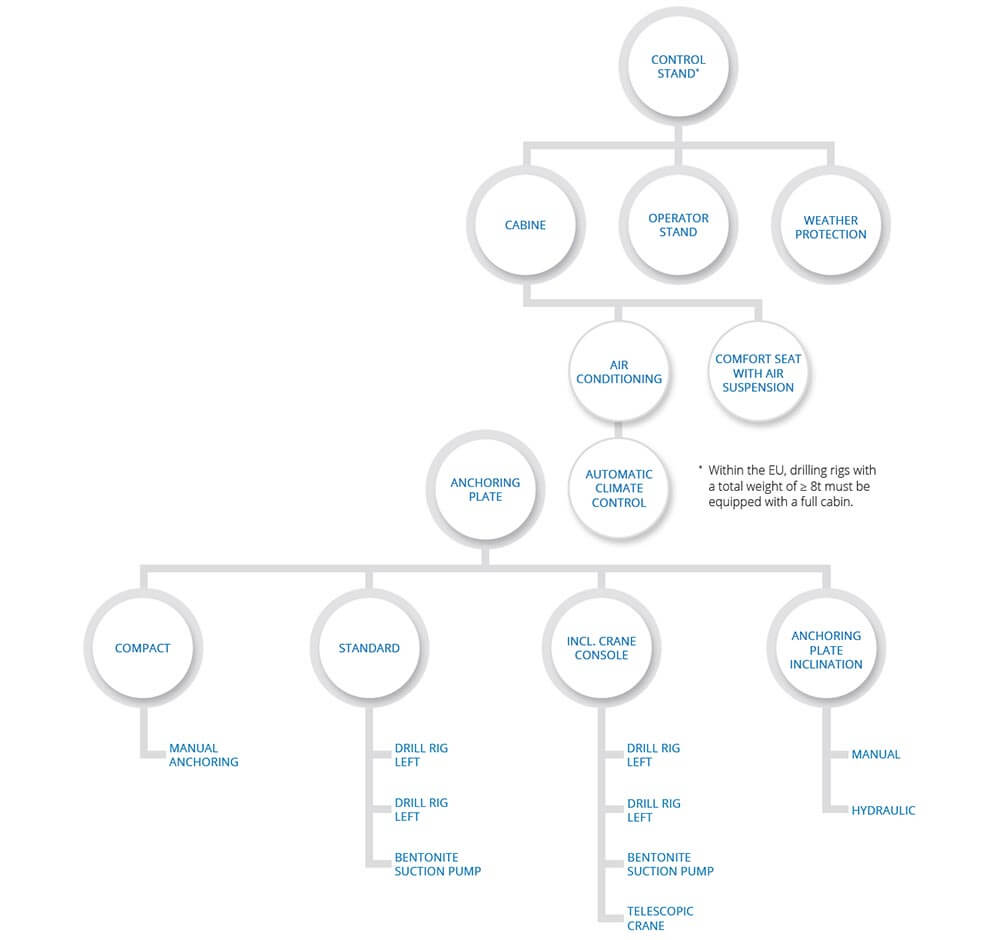

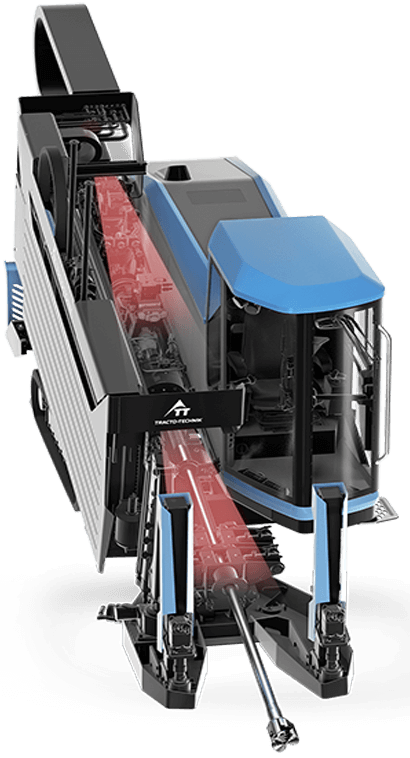

- FLEXIBLE MODULAR CONCEPT

The modular construction for different machine sizes and a multitude of options allow the user to configure his drilling rig from this kit according to his individual requirements.

- PRODUCTIVE PEAK PERFORMANCE

The modular construction for different machine sizes and a multitude of options allow the user to configure his drilling rig from this kit according to his individual requirements.

- ROCK DRILLING IN ALL PERFORMANCE CLASSES

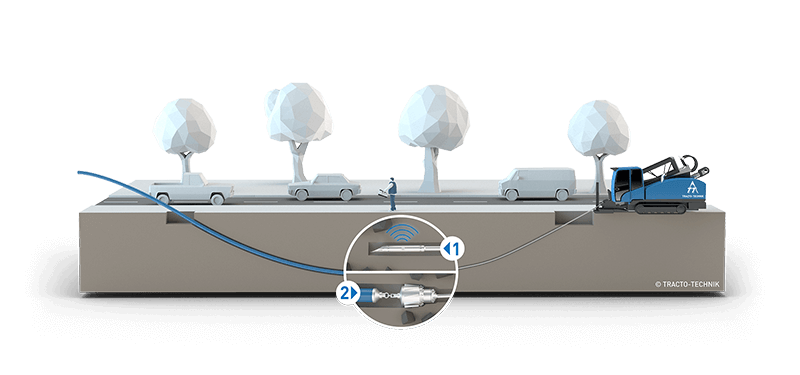

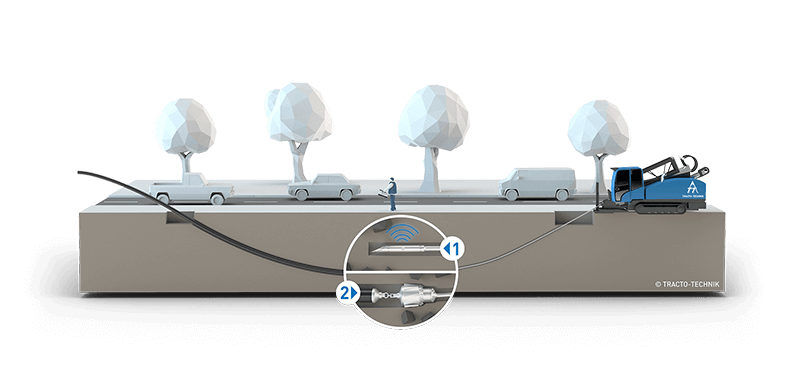

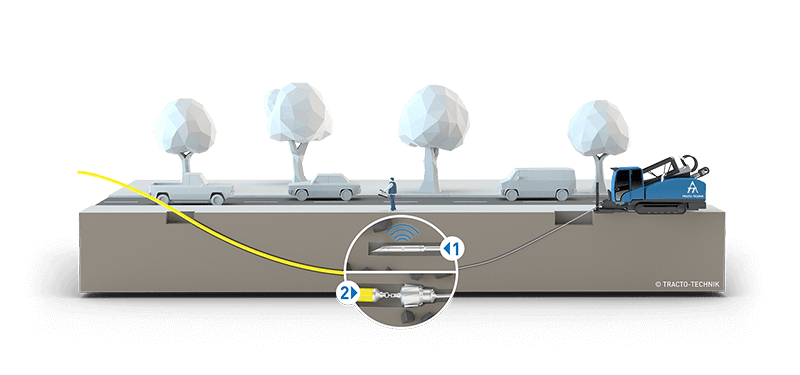

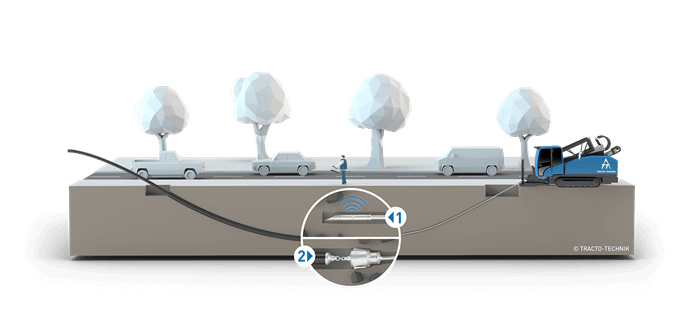

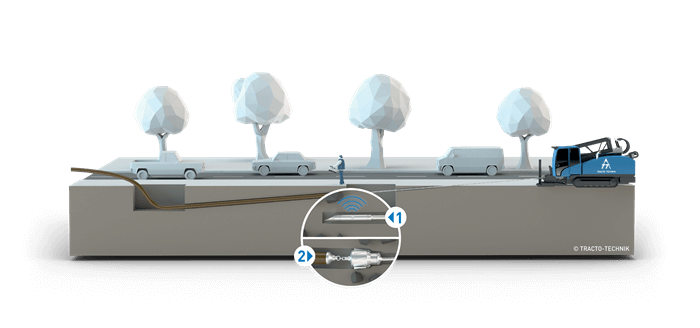

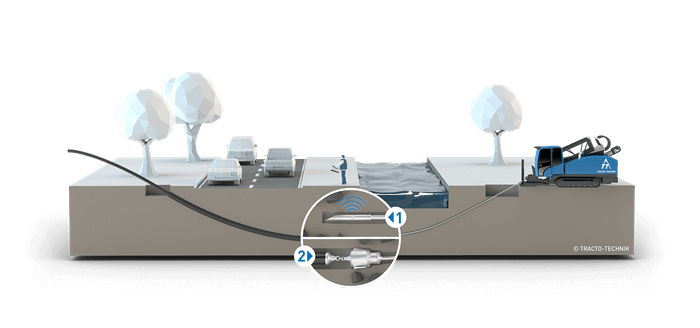

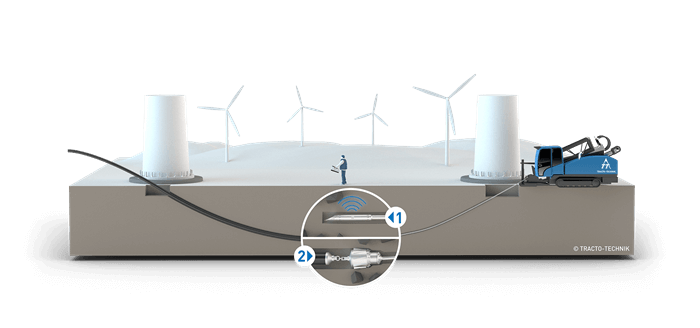

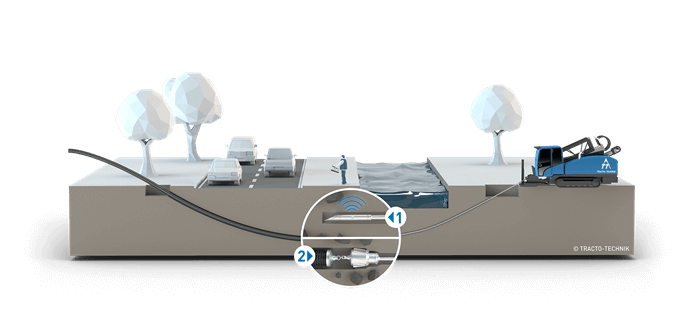

Due to the unique machine concept, the complete series can be used as a Jet Condition System (JCS) with normal rods in conventional soils, or as an All Condition System (ACS) with twin-tube rods in complex geologies and rocks.

- REMOTE CONTROLLED DRILLING

The extensive automation of all processes enables remote-controlled drilling with the help of a specially developed, innovative remote control.

- DIGITAL SOLUTIONS

Intelligent software solutions that centrally link planning, execution, billing, documentation and service, allow for individual control and increase of productivity.

- INTUITIVE OPERATING CONCEPT

The intuitive operating concept, with almost all functions of the drilling rig being controlled via a central touch screen, is consistently tailored to the needs of the operator. This allows ergonomic and fatigue-free working with an increased degree of automation.