PINPOINT ACCURACY

The Horizontal Auger boring method is a reliable static process for installing sewer house connections as well as product and steel protection pipes under streets and railways tracks. Installations can be either steered or non-steered. With the steered method in sewer construction, high levels of on-target precision required in sewer construction can be achieved.

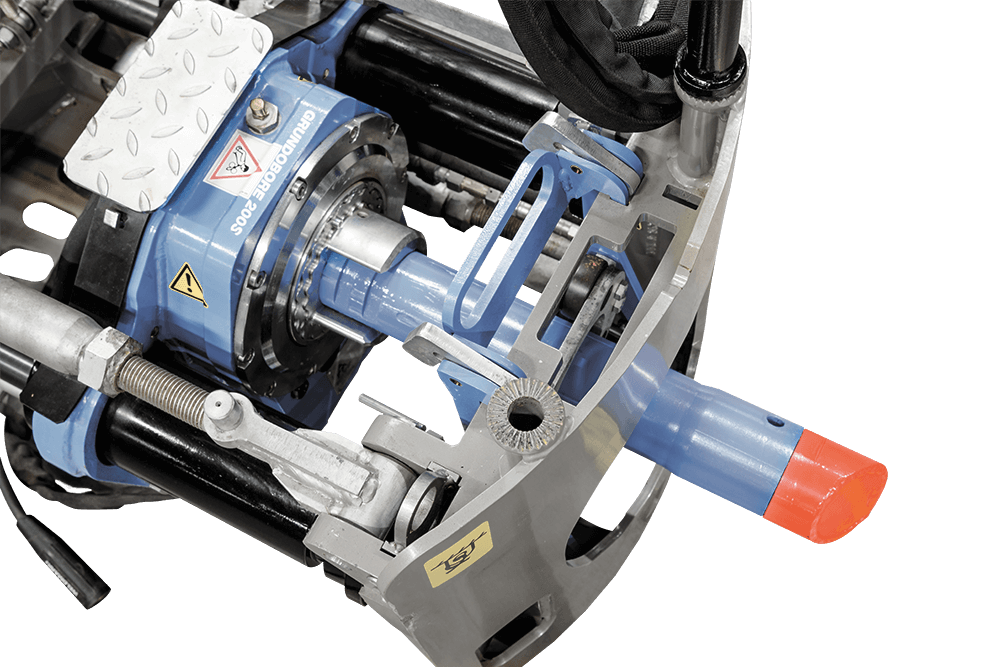

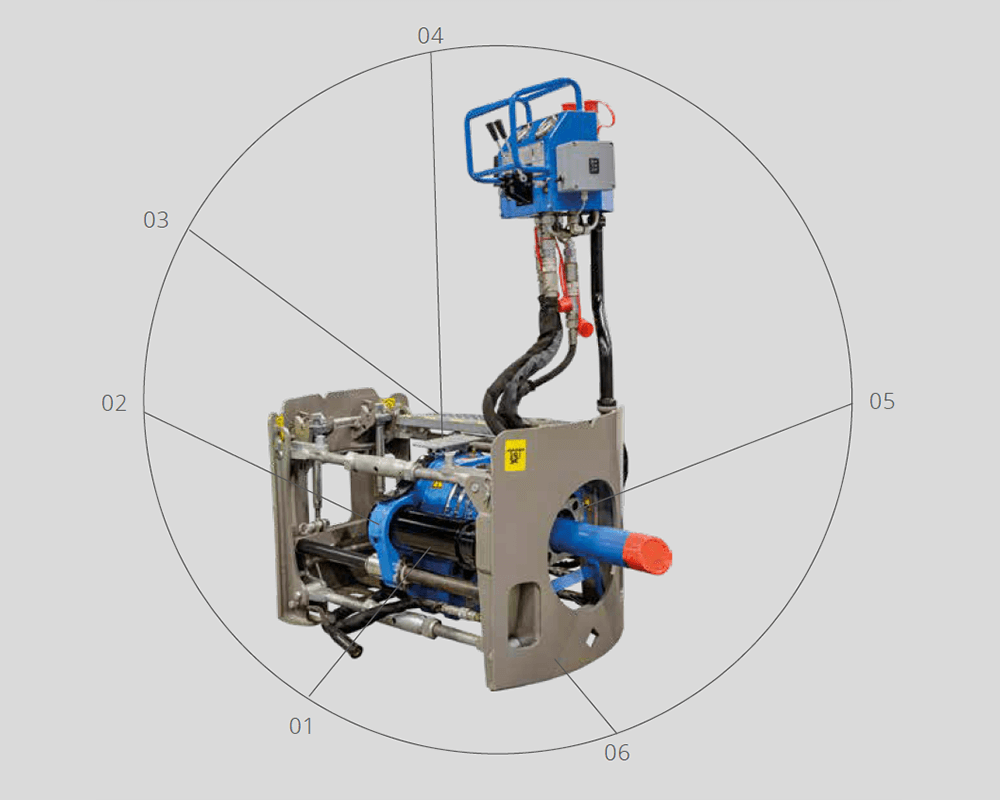

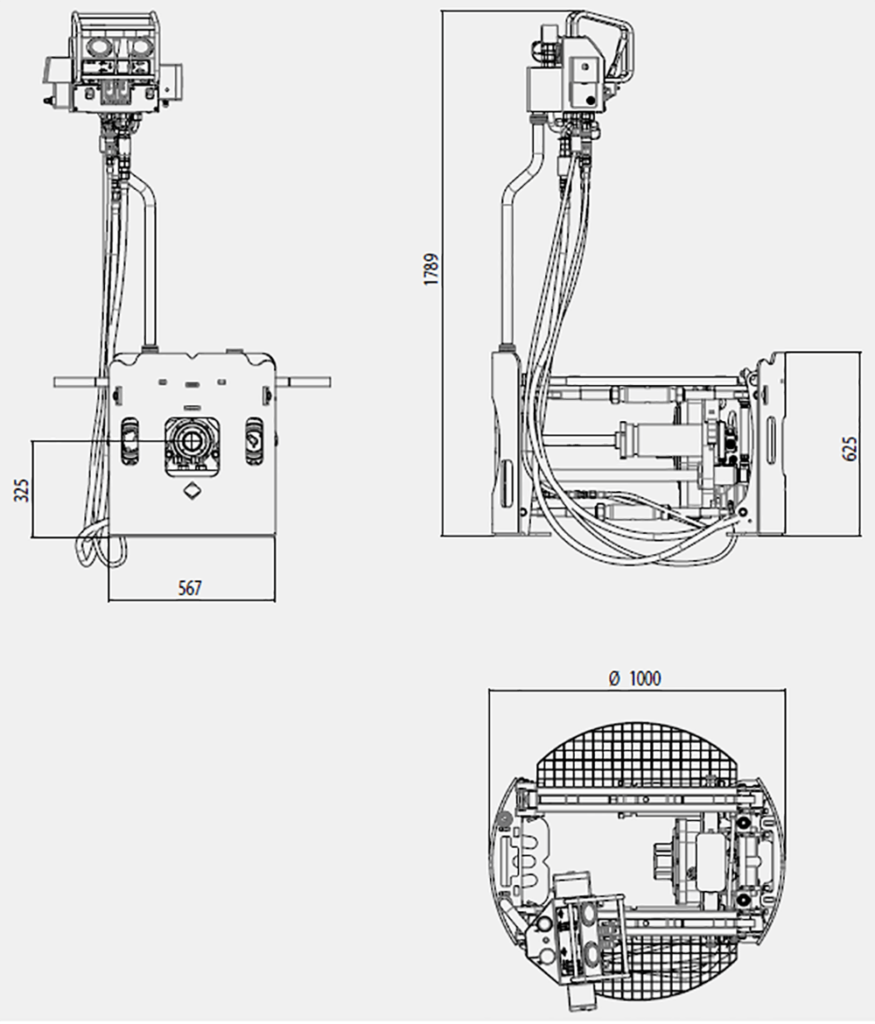

The compact GRUNDOBORE 200S is powered by an external hydraulic station with hydraulic drive energy and is particularly suitable for installing sewer house connections and product and protection pipes up to DA 280.

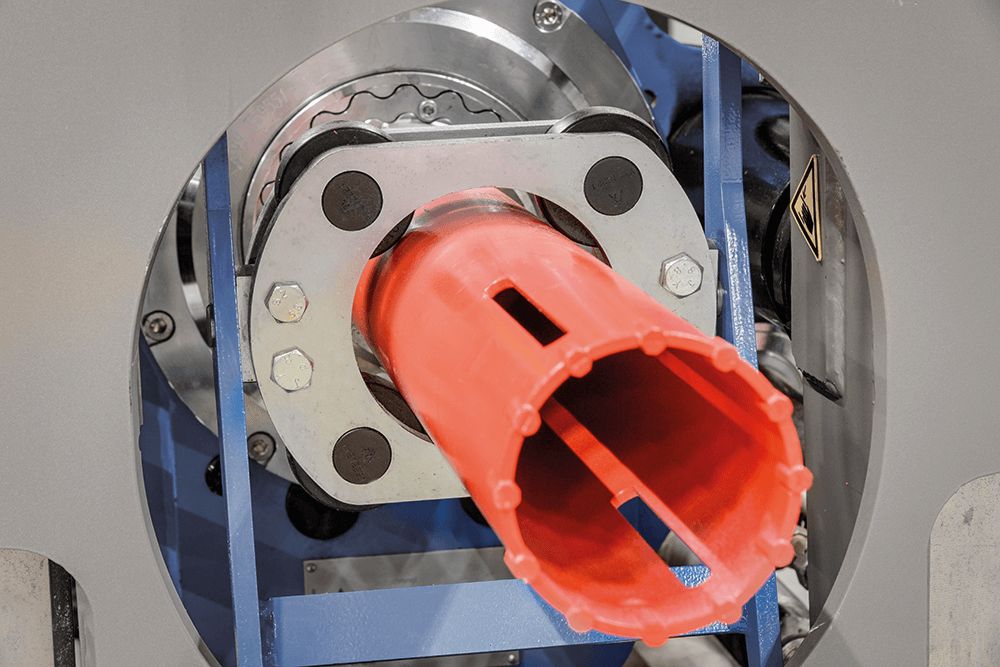

Since the GRUNDOBORE 200S support frame and auger boring unit can be installed separately, launching is possible from a 1 m-manhole or exceptional small work pit.