GRUNDODRILL – 18ACS

KING OF ROCK

TRAILBLAZER

MAKES AN IMPACT IN ALL SOILS

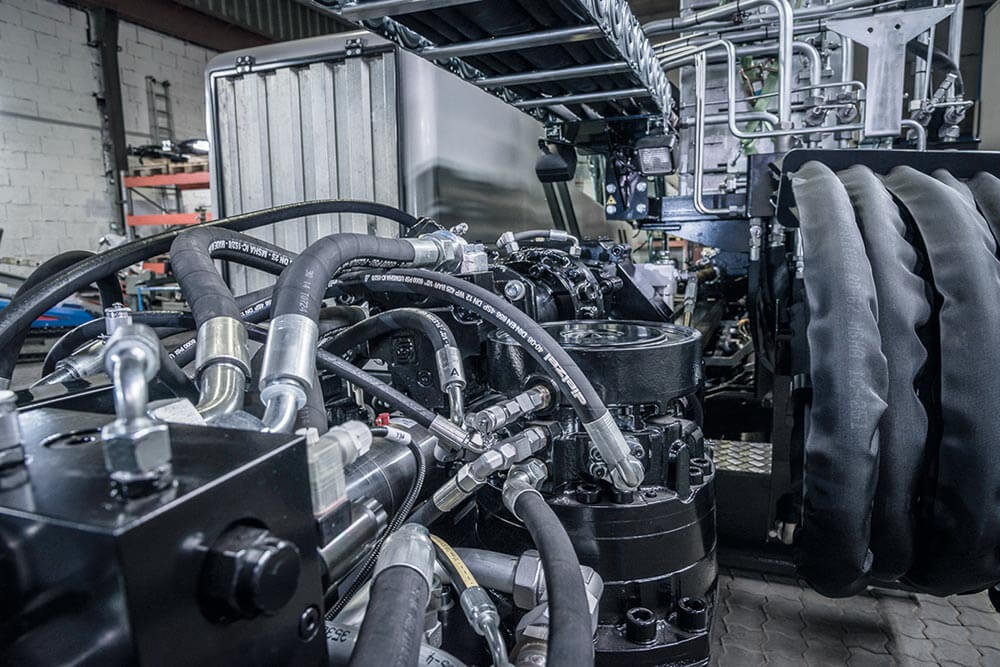

IDEAL POWER RATIO

- Stepless adjustment of torque and speed for maximum rotational power and maximum productivity at any speed

- Best possible adaptation to demands and soil conditions

RODS FOR EVERY PURPOSE

- Rods TD73 and TD82 for fluid-assisted drilling

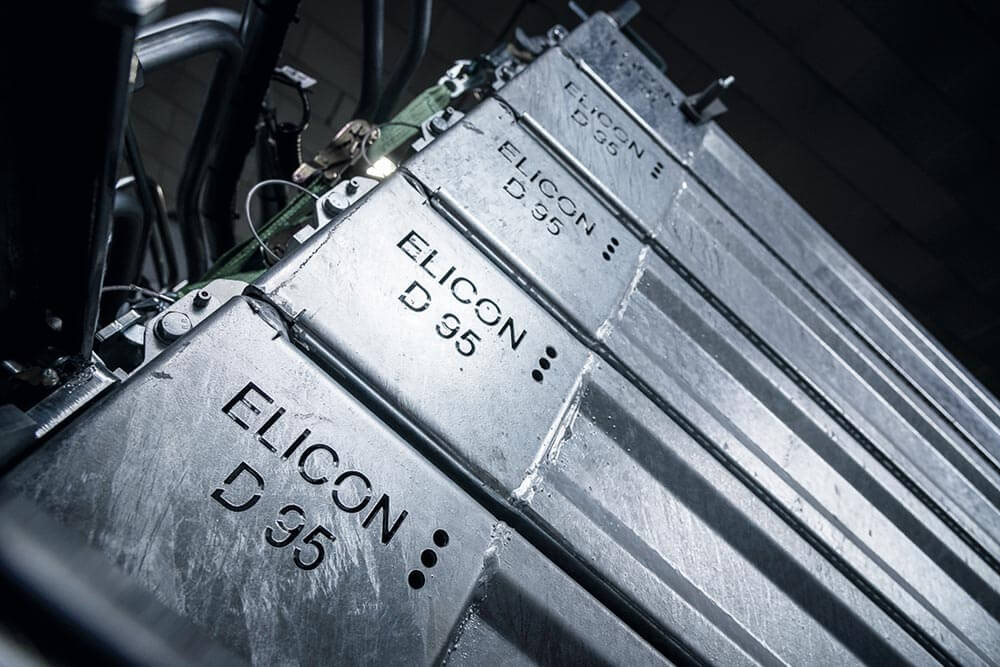

- Twin-tube rods Elicon 95 for rock drilling

- Quick conversion from fluid-assisted to rock drilling

LIGHTNING-FAST ROD EXCHANGE

- Fully automatic operation ensures minimal downtime, maximum productivity and relief for the machine operator

- The on-board crane facilitates easy handling of the rods, stacking boxes and additional components

- Rotation of drill rods within rod box possible during normal operation, which results in consistent use and consistent wear of the rods

CABLE-GUIDED DRILLING

- The GRUNDODRILL 18ACS and the GRUNDODRILL 18N can optionally be converted for cable-guided bores when drilling in challenging terrain and at great depths

- Cable-guided drilling is also possible in connection with EL95 twin-tube rod system

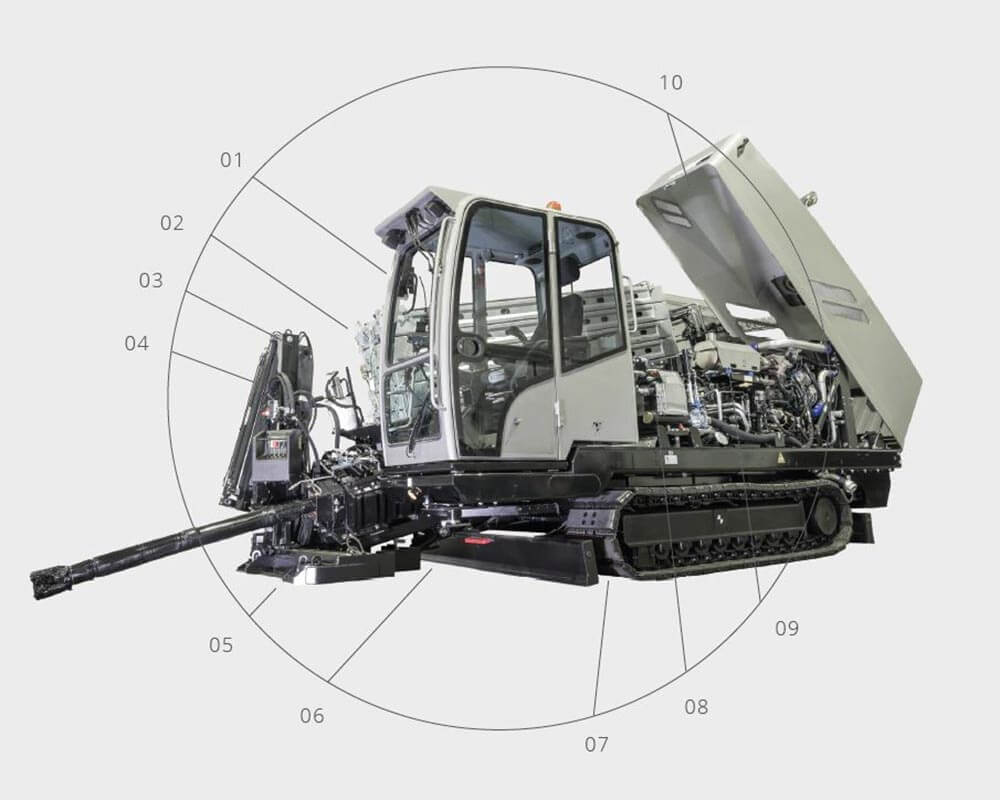

01. Hydraulically-adjustable and vibration – dampened comfort cabin – user-friendly, clear layout, can be positioned flexibly

02. Large rod magazine – up to 225 m drill rods on board (with TD73 equipment)

03. Anchoring system for enhanced stability while drilling

04. Hydraulic loading crane for self-sufficient handling of optional stacking boxes, drilling rods and attachments

05. Bentonite collecting tray – optionally with Bentonite suction pump

06. Two stabilisers – maximum stability, variable inclination of the cradle for an ideal penetration angle

07. Broad undercarriage – with rubberised steel tracks – extremely mobile and self-supporting

08. High performance bentonite pump – for rapid reaming speed and large reaming diameters

09. Diesel engine with the highest output of its class – low fuel consumption, low noise and emission levels

10. Large GRP hood – easily accessible for service and maintenance

GROUND CONTROL FULL VISION, MAXIMUM COMFORT

MAXIMAL OPERATOR COMFORT

Different operating modes that can be freely selected by the machine operator:

All machine functions controlled by the machine operator

Memory functions for rotation and thrust, Automatic paddle mode, Automatic rod exchange mode, Automatic reloading for rod magazine

incl. automatic drilling, automatic rod exchange, rod lubrication and cleaning, etc.

TOP NOTCH WORKPLACE

- Panel PC with touchscreen and internet connection

- High-resolution colour display

- Language selection

- Automatic drill data log according to DVGW standards

- Remote diagnosis with telemetry data transfer

- LED lighting

- Radio with Bluetooth hands-free system, CD drive and USB port

CUSTOM ERGONOMICS

- Grammer comfort seat XL

- Air suspension with automatic weight adjustment

- Can be adjusted individually

- Seat heater

- Fabric upholstery

- Panorama glazing for optimum overview

- Stepless hydraulically swivelling cabin

- If required, work can also be carried out with the cabin in transport position, e.g. in confined spaces

- Heating and air conditioning

- Cummins motor Tier 4 final, Stage IV for driving and drilling, 119 kW

- Stepless adjustment of torque and rotational speed for maximum rotation and highest level of productivity at any speed

- Drill rig with rubber track undercarriage, stabilisors

- Wireless remote control

- Spacious cabin, comfortable seat, joysticks, panel PC with touchscreen, air conditioning

- Automatic bore mode

- Fully automatic rod exchange system

- Fully automatic clamp and break-away facility

- Anchoring system with drilling fluid collecting tray

- Powerful HP Bentonite pump on board the rig

- Bore data logging – data transfer

- High-pressure cleaner

- Optionally with drill rod type TD73 or TD82

Thanks to trenchless technology, electrical power on the North Sea island of Sylt will soon only flow underground. Schleswig-Holstein Networks AG (SH Netz) has invested an impressive €16.5 million to optimise the power supply and to dismantle more than 7 km of 60,000 volt overhead lines.

For the new underground supply, a 15 km long, 110.000 V power line weighing around 800 t and was installed through the bottom of the North Sea and continued from there via a new high-voltage land cable to the transformer station on the island in Keitum.

The installation of the empty pipes for the connection of the sea cable in the mudflats and the power cables on the island was a case for the Nodig professionals from the contractor Paasch, who mainly applied the HDD method for this task.

TECHNICAL SPECIFICATIONS

| PERFORMANCE DATA | GRUNDODRILL 18ACS DRILL ROD ELICON 95 (ROCK) | GRUNDODRILL 18ACS / 18N DRILL ROD TD73 / TD82 |

|---|---|---|

| Thrust and pullback force [kN]: | – | 180 · 200 (40 – 45 lbf) |

| Max. feed rate (without load) [m/min]: | 36 (118 ft/min) | 36 (118 ft/min) |

| Max. torque (outer rod) [Nm]: | 7.500 (5,532 lbf ft) | 7.500 · 10.000 (5,532 · 7,376 lbf ft) |

| Max. torque (inner rod) [Nm]: | 2.500 (1,844 lbf ft) | – |

| Max. spindle speed (outer rod) [rpm]: | – | 180 |

| Max. spindle speed (inner rod) [rpm]: | 350 | – |

| HP Bentonite pump P72/320 · P72/400 [l/min]: | 320 · 400 (85 · 105 gpm) | 320 · 400 (85 · 106 gpm) |

| Bentonite pressure [bar]: | 90 (1,305 psi) | 90 (1,305 psi) |

| Rod magazine contents [m]: | 120 (394 ft) | 225 · 210 (738 · 689 ft) combi-box |

| Number of rods [pcs]: | 40 | 75 · 70 |

| Drill rod Ø [mm]: | 98/95 (3.86/3.74 in) | 73/63 · 82 (2.87/2,48 · 3.23 in) |

| Effective rod length [mm]: | 3.000 (118 in) | 3.000 (118 in) |

| Rod weight [kg]: | 80 (176.4 lbs) | 42 · 46 (92,6 · 101.4 lbs) |

| Pilot bore Ø [mm]: | 165 (6.50 in) | 115 · 140/170 (4,53 · 5,51/6.69 in) |

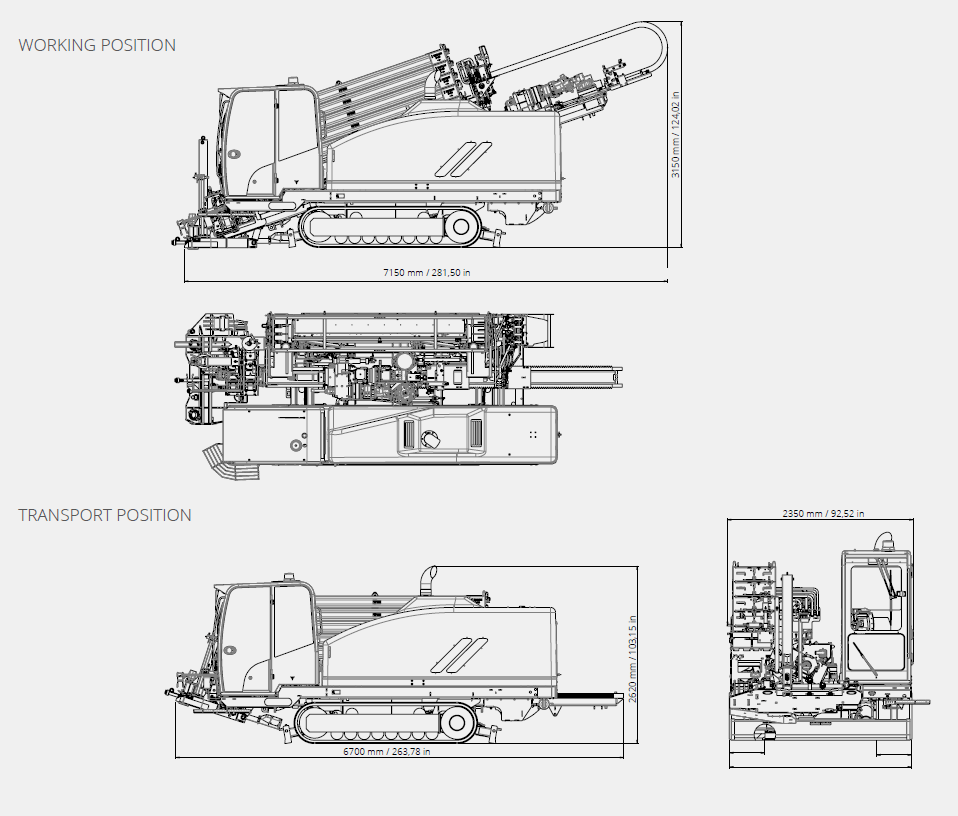

| L x W x H (transport position) [mm]: | 6.700 x 2.350 x 2.620 | 6.700 x 2.350 x 2.620 |

| L x W x H (transport position) [in]: | 263,78 x 92,52 x 103,15 | 263,78 x 92,52 x 103,15 |

| L x W x H (working position) [mm]: | 7.150 x 3.050 x 3.150 | 7.150 x 3.050 x 3.150 |

| L x W x H (working position) [in]: | 281.50 x 120.08 x 124.02 | 281.50 x 120.08 x 124.02 |

| Max. weight with EL 95, combi box [kg]: | 15.350 (33841 lbs) | 15.350 (33841 lbs) |

| Engine manufacturer: | Cummins | Cummins |

| Engine model: | QSB4.5 | QSB4.5 |

| Emissions standard: | T4 final | T4 final |

| Max. engine output [kW]: | 119 (162 hp) | 119 (162 hp) |

| Tank capacity Diesel / AdBlue [l]: | 180/22 (47,6/5,8 gallons) | 180/22 (47,6/5,8 gallons) |

| Fresh water tank capacity [l]: | 105 (27.7 gallons) | 105 (27.7 gallons) |

| Sound pressure level LP / Sound power level LW [dB(A)]: | 64.9/99 | 64.9/99 |

| Workplace vibrations [m/s²]: | ≤ 0.5 | ≤ 0.5 |

| Inclination angle: | 0° – 30° | 0° – 30° |

| Max. driving speed [km/h] 2 stages: | 1,3/2,2 (0.8/1.4 mph) | 1,3/2,2 (0.8/1.4 mph) |

| Upsizing Ø* [mm]: | ≤ 600 (≤ 24 in) | ≤ 600 (≤ 24 in) |

| Outer pipe Ø* [mm]: | ≤ 500 (≤ 20 in) | ≤ 500 (≤ 20 in) |

| Bore length* [m]: | ≤ 400 (≤ 1312 ft) | ≤ 400 (≤ 1312 ft) |

* depending on ground